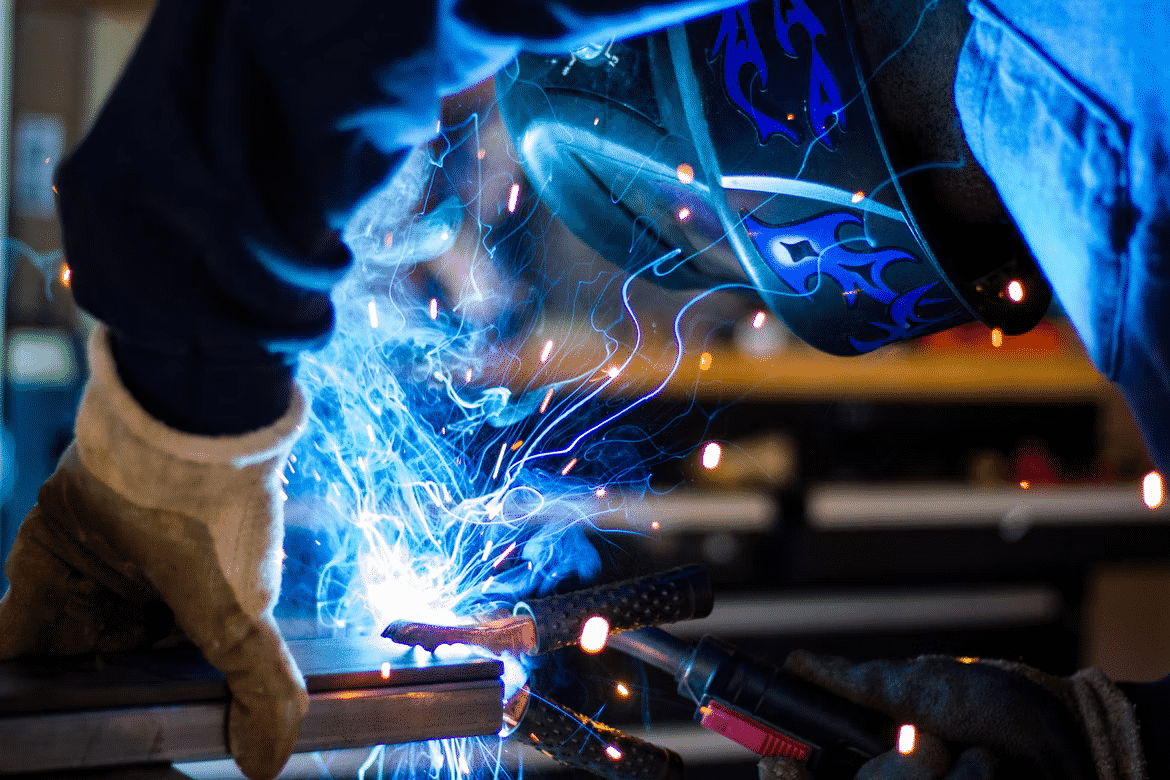

When you work in a certain industry, especially one that requires you to work with your hands it is imperative to understand the details of what you’re working with. When starting out as a welder, it is important to understand what goes into the welding process, as well as the different types of welding techniques that are available and how they work.

MIG welding is known for its versatility, as it allows you to weld a wide range of metals. On the other hand, TIG welding offers greater control and precision when working with thinner or more delicate materials. While both methods have their own benefits and drawbacks, there are some key aspects that set these two techniques apart. So, whether you’re a beginner welder or a seasoned expert, it’s important to understand the key differences between MIG and TIG welding. In this article, we’ll help you explore the main differences between MIG and TIG welding.

The Process

Both MIG and TIG welding processes are a part of the arc welding process. The difference between both lies in the way arc is used in the process. Metal Inert Gas (MIG) welding is also known as gas metal arc welding which involves the use of a continuous wire electrode as the filler material in order to create a strong and lasting bond. This electrode melts to provide the requisite filler metal to cover the root gap between the metals and therefore is known as a consumable electrode. This creates a pool of molten metal, which cools and hardens to create a strong joint. To protect the weld puddle from impurities and oxidative processes, the MIG weld technique uses an inert shielding gas. The shielding gas utilized in the process is typically a mix of 75% argon and 25% CO2.

On the other hand, TIG-Tungsten Inert Gas Welding or Gas Tungsten Arc Welding uses a non-consumable tungsten electrode to produce an electric arc that melts metal filler rods into the joint area between two metals being welded together. The heat from the electrode only melts the material rather than the tungsten electrode as compared to the consumable electrode process of MIG. TIG welding uses shielding gas which is usually 100% argon or helium as compared to the argon and CO2 mix used in MIG welding.

Weld Difference

Speed:

The speed at which the weld may be applied is another distinction between MIG and TIG welding. A MIG welder can lay down a weld bead at a quick rate, but TIG welding requires constant manual application of a welding rod. A proficient TIG welder can produce a weld bead in a short amount of time. However, a TIG welder can seldom outperform a MIG welder in terms of speed. This is because of the TIG welding process’s manual nature. The MIG technique is often utilized in automated welding procedures because it can produce a weld in a speedy and uniform manner.

Precision:

When it comes to precision, TIG wins the round as it employs a more focused and controlled arc which is assisted by pedal control. The people behind Metal Marker say that this sharply focused torch yields a stronger weld output with greater precision when compared to MIG welding. This is why TIG welding is used more while fabricating artistic and ornamental products, whereas MIG welding is used for larger objects.

Finish:

Under the hood, MIG welders may outperform TIG welders, but they never look as attractive. A skilled MIG welder may produce a neat weld that is pleasing to the eye, but it cannot compete with a good TIG weld. TIG welds always have a finer pattern and a tight uniform bead. They seldom have splatter and generally, only require a little removal of undesired color. Exposed welds, such as uncoated stainless steel items, are nearly always TIG-welded since they complete the process more neatly. MIG welds are thicker; they frequently produce splatter and struggle to achieve the same exquisite quality.

Application of TIG & MIG weld

MIG:

When thicker material or larger parts need to be welded, the rapid and efficient MIG technique is the way to go. The MIG process can handle several lengthy runs, thanks to its constantly supplied wire and less complex equipment. The TIG process, on the other hand, necessitates several pauses and starts in order to get fresh rods or modify the rod in your hand. MIG welders do not require such extensive training as TIG welders, which lowers manufacturing costs and makes the undisputed choice between both, only when precision is not demanded.

MIG welding is commonly used in automotive repairs and manufacture, metal component repairs, construction welding, pipe welding, shipbuilding, underwater welding projects, and railway track maintenance, among other applications. This wide range of MIG welding jobs demonstrates how adaptable the technique is. You can use MIG welding for your project if it doesn’t need to appear flawless, requires speed for completion, or contains heavier metals that TIG welding won’t work on.

TIG:

When working with thin and nonferrous materials, TIG welding is the superior option. TIG welding’s accuracy and precision make it ideal for thin materials that are prone to warping. It’s best used in situations where both aesthetics and strength are important. TIG produces a clean finish on the operated material with no visible weld filler above the surface.

TIG welds are ideal for stitching together vehicle body pieces, aerospace components, ship parts, bicycle parts, and pipes since there is no visible filler when they are done. The corrosion resistance and strength of TIG welds are especially important in these applications.

TIG welding is also used for the construction of nuclear fuel rods. If you have welding experience and require a robust, corrosion-resistant, visually beautiful connection, as well as have the time to spend on the operation, then TIG is the only way to go.

So, if you’re ready to start welding, be sure to invest some time in learning about the unique benefits of both MIG and TIG welding techniques. With the right knowledge under your belt, you’ll be well on your way to mastering this exciting skill for years to come!